SOLUTIONS

We handle our projects with customers' specifications met perfectly. We develop a comprehensive range of services for our clients' selection every year. We are your reliable supplier.more info

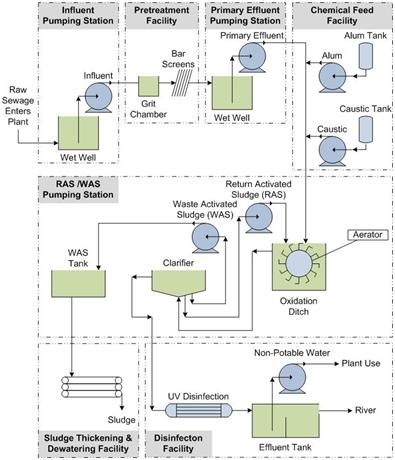

SummaryWe were subcontracted to complete the SCADA programming due to our expertise in this area. The original control system was installed in the early 1990’s and had was became obsolete and high maintenance. The process overview is shown in the figure below.

In the figure above you can see the 7 distinct areas which each had it own PLC and HMI. The PLC’s used were Allen-Bradley CompactLogix’s, and the local HMI were PanelView Plus’s. For supervisory-level monitoring and control Allen-Bradley FactoryTalk View Site Edition (SE) was used. The View SE system consisted of a primary and secondary server with 3 clients. Reports were also generated using data from MSSQL data tables on the SE Server.

Reducing Project Schedule, Project Cost, and Total Cost of OwnershipWe were able to reduce the project schedule, project cost, and total cost of ownership by applying ISA S88 standard design philosophy. The PLC software was written following ISA S88 which is for batch control. The wastewater process is continuous, but we can leverage the S88 design philosophy to reduce the project cost, project schedule, and cost of ownership. Cost and schedule are both reduced because writing software using the ISA S88 standard lends itself to agile software development which reduces cost because of its iterative nature. S88 is a module style of code writing who parts can be reused. We first developed modules of code called control modules (CM’s) which in our case was code for a specific device like motors, valves, drives, etc. The CM’s had simulation software built into them so they can be simulated independently or in an entire system. The PLC code was then tested with the HMI code for developed CM’s in bi-weekly iterations until complete. Then equipment modules (EM’s) were developed for the specific areas of the process. An EM is group of equipment motors, valves, drives, etc. so in our case the EM’s are made up of CM’s. The saving occurs because once the CM is coded and tested it is used for every like device, so for instance every motor in the facilities uses the same CM code. The motor CM code in the 7 PLC’s is identical. The EM’s start as a template and modified slightly based on the area. Because over 50% of the code is reused this also contributed to the savings. Total cost of ownership for 2 main reasons. First the code is more reliable because every device is using the identical CM and the EM is easier to trouble shoot. So the need for ongoing support is almost eliminated. Second because of the codes robustness it is easier to operate and maintain requiring less attention.

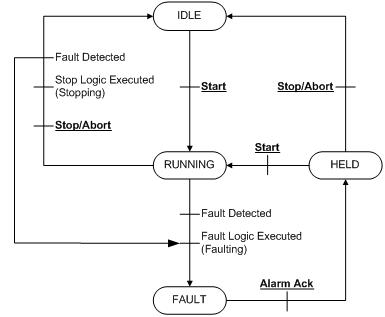

Design Details OverviewSince we followed the S88 design philosophy our EM has idle, running, stopping, held, faulting, and fault as the equipment states. Operator commands start, stop/abort, and alarm ack are shown in bold underlined text, see the figure below. The stopping and faulting states are intermediate states while equipment is going to its required state. For example to stop the equipment the operator presses the Stop/Abort pushbutton and the EM state changes from running to stopping then to either idle or faulting to fault.

The individual CM code was developed as an add-on instruction were the data types are user defined. Using data types that are user defined allows us to reduce the first level of base name controller tags which simplifies viewing the tags.

Project DemonstrationPlease contact use to see working demonstration of this project, the demo uses our ControlLogix PLC and a laptop computer. We could be happy to review the PLC and HMI design philosophy to show you how we can reduce your programming cost by 20-40% or more.